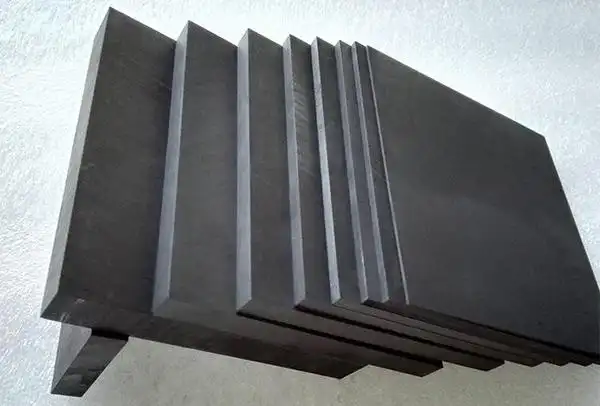

Graphite Extruded Polystyrene (SXPS) is a high-performance thermal insulation material. Its main raw material is polystyrene resin, with added graphite powder and additives. It is formed into a honeycomb-like closed-cell structure through a special extrusion process. Its main characteristics and applications are as follows:

I. Core Characteristics

Excellent Thermal Insulation

With a thermal conductivity as low as 0.026–0.028W/(m·K), the graphite particles enhance thermal reflectivity, resulting in significantly better insulation than traditional extruded polystyrene boards.

High Compressive Strength and Moisture Resistance

Closed-cell rate is above 99%, with high compressive strength and extremely low water absorption (<1%), ensuring stable performance in long-term humid environments.

Environmental Protection and Durability

CO₂ foaming technology is used instead of Freon, reducing ozone layer depletion; its physical properties are stable, with a service life exceeding 50 years.

Fire Performance

Some products can achieve a B1 fire rating (flame-retardant material) through modification, enhancing building safety.

II. Application Scenarios

Building Insulation

Exterior wall/roof insulation layer

Basement moisture and heat insulation

Integrated insulation system (such as patented fixed airbag structure).

Underfloor Heating System

Used as a dedicated insulation layer for underfloor heating, reducing downward heat loss.

Cold Chain and Industrial Applications

Refrigerated trucks, cold storage insulation, solar system insulation layer.

Special Engineering

Plaza ground, road and bridge engineering (compressive resistance and anti-settlement).

TAG:

Graphite extrusion board

Category:

Other content

Triangular truss steel structure