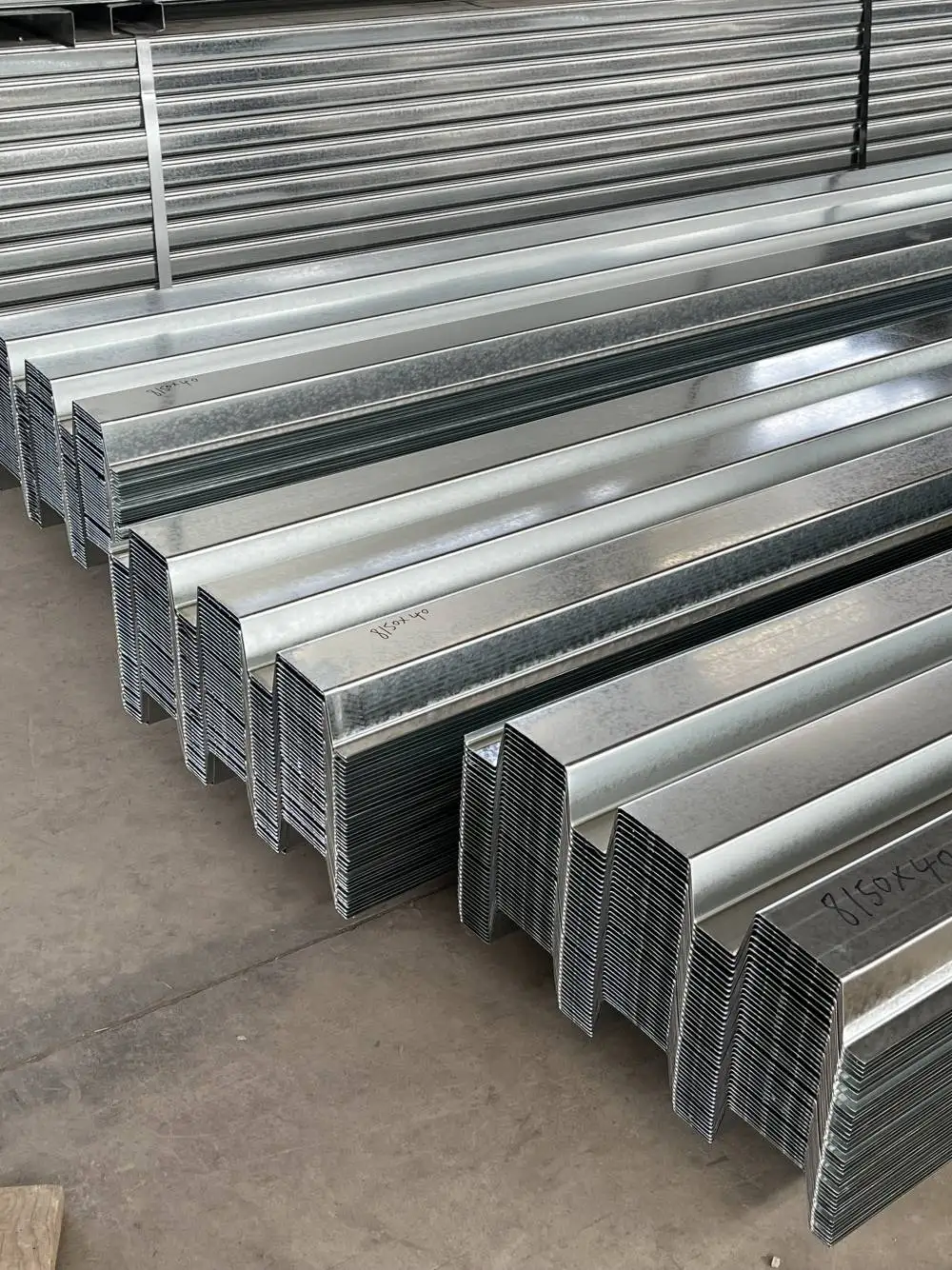

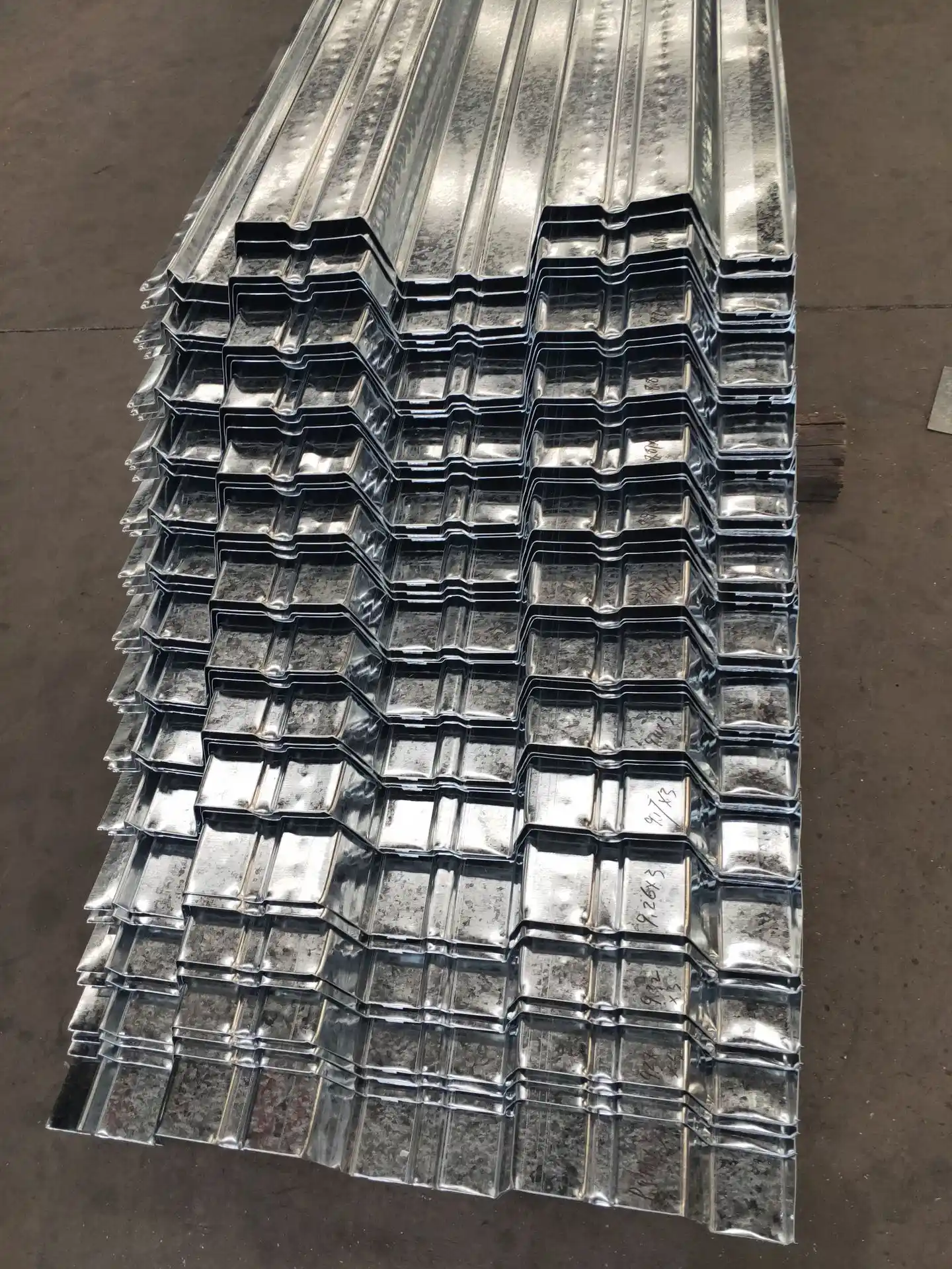

Steel sheets pressed and formed to support concrete floor slabs are called profiled steel sheets, also known as floor decking or steel decking. They are divided into three categories: open floor decking, closed floor decking, and closed-end floor decking.

Research and Development Process

Floor decking is divided into three generations of products: open floor decking, closed-end floor decking, and closed floor decking.

First Generation Folded Open Floor Decking

It is only used as a permanent formwork for floor slabs and cannot work together with concrete. The stress analysis is complex, so this type of floor decking is only used as a permanent formwork during construction. After the concrete reaches 75% strength, the board no longer plays any role. The budget department has calculated that the overall cost of this type of floor decking in the project is 1.6 times the cost of cast-in-place construction. Including YXB76-305-915, YXB51-305-915, YXB75-200-600, YXB50-250-750, YXB35-125-750;

Second Generation Folded Closed-End Floor Decking

In this case, designers improved the plate type by reducing the opening of the plate, which is the closed-end plate, also known as the swallowtail plate. This plate type can not only work together with concrete but also reduces the area of concrete height weakening. It also greatly improves the fire and corrosion resistance of the plate, and the floor slab stiffness is also higher than that of the open composite plate. Including YXB51-200-600;

Third Generation Folded Closed Floor Decking

Considering the above problems, some designers added shear slots to the original floor decking surface. Through the wrapping effect of concrete, the two work together to increase the strength of the floor slab. It can not only make the floor decking and concrete a whole but also save some tensile reinforcement. This greatly reduces the project cost. After improvement by designers, the second generation of closed and closed-end floor decking gradually replaced the first generation of open floor decking. Including YXB65-185-555, YXB66-240-720, YXB65-170-510, YXB46-200-600, YXB40-185-740.

Steel Bar Truss Floor Decking

In order to solve many shortcomings of the first and second generations of steel decking, such as the smaller building net height, engineers developed the third generation of steel bar truss steel decking. The third generation of floor decking is formed by changing and reducing the original floor decking convex profiled shape. The steel bars in the floor slab are processed into steel bar trusses in the factory using semi-automatic sheet metal welding equipment to replace the convexity and bearing capacity of the floor decking. After welding, rust prevention and environmental protection processes such as silanization, pure manganese phosphating, washing, drying, and galvanizing are used. The steel bar truss and floor decking are integrated into a combined formwork in the factory using high-frequency resistance welding. This formwork system combines the reinforcement of the concrete floor slab with the construction formwork into one, forming a load-bearing component that can withstand the self-weight of wet concrete and construction loads during the construction stage. During the construction stage, this component can also be used as lateral support for steel beams. During the use stage, the steel bar truss and concrete work together to withstand the use load.

1. The stress mode and combination mode of the truss floor slab are reasonable, with the overall rigidity of cast-in-place concrete. It can easily complete two-way slab construction and use, while ordinary profiled plates cannot place steel bars perpendicular to the rib direction in the lower skin.

2. In construction, with a beam spacing of more than 3 meters, ordinary profiled plates basically need to add temporary supports; the maximum unsupported spacing of steel bar truss formwork can reach 5 meters.

3. Temporary openings on the truss formwork basically do not require reinforcement, and the laying of electromechanical lines and pipes is convenient.

4. The steel plate does not participate in stress, does not require fire-resistant and anti-corrosion coatings, and there is no need to worry about repair problems after fire, which is both safe and economical. The bottom of the plate is flat, the net height is guaranteed, the floor slab has consistent two-way stiffness, good seismic performance, solves the problem of two-way reinforcement of closed plates, and the steel bar spacing and concrete protection layer thickness are guaranteed.

5. Two-way slab design and construction are simple and suitable for large-span factories. The plating is reasonable, the stud welding quality is reliable, and no penetration welding is required at the ends, and the floor slab has good shear performance.

6. Rust prevention and anti-corrosion processes such as silanization, phosphating, washing and drying, and galvanizing are used, and sealed and stored away from light.

Product Applications

Products are widely used in steel structure buildings such as power plants, power equipment companies, automobile showrooms, steel structure factories, cement warehouses, steel structure offices, airport terminals, train stations, stadiums, concert halls, grand theaters, large supermarkets, logistics centers, and Olympic venues.

It meets the requirements of rapid construction of main steel structures, can provide a firm working platform in a short time, and can use multiple layers of profiled steel sheets, and layered pouring of concrete slabs for continuous construction.

Main Features

1: Meets the requirements of rapid construction of main steel structures, can provide a firm working platform in a short time, and can use multiple layers of profiled steel sheets, and layered pouring of concrete slabs for continuous construction.

2: In the use stage, the floor decking serves as the tensile reinforcement of the concrete floor slab, which also improves the stiffness of the floor slab and saves the amount of steel bars and concrete.

3: The embossed surface of the profiled plate creates the maximum bonding force between the floor decking and the concrete, making them form a whole. With the addition of stiffening ribs, the floor decking system has high-strength bearing capacity.

4: Under cantilever conditions, the floor decking only serves as a permanent formwork. The length of the cantilever can be determined according to the cross-sectional characteristics of the floor decking. In order to prevent cracking of the cantilever plate, negative reinforcement should be added at the support according to the design of the structural engineer.

Process Flow

Visual inspection: The flatness of the plate should be less than 3mm, there should be no obvious unevenness, distortion, the galvanizing layer should be greater than 120g/, there should be no scratches, and residual welding slag. The weld points should be firm. The surface should not have contaminants that affect cement setting.

The construction process of floor decking is generally as follows: line marking → cleaning the plate → hoisting → laying the plate → cutting → pressing → side welding → end welding → leaving holes → sealing → inspection → stud welding → laying reinforcement → embedded parts → pouring → curing. Of course, so many processes cannot be separated from good labor organization, and the following processes can also be handled according to the actual on-site situation. Labor organization should be divided into two groups,

The first group is responsible for material handling, including material cleaning and transportation, until the floor decking is accurately and correctly hoisted to the construction site according to the construction progress, including 5 crane workers;

The second group is responsible for laying, including steel bar laying, cutting, installation, and hole reservation. Each group consists of 3 people, responsible for one section, with 4 groups working simultaneously on the same working level. Specialized personnel should be assigned to maintain the laid decking plates during the subsequent reinforcement binding and concrete pouring processes. The specific methods are:

(1) First, mark the centerlines of the steel beams in the plate laying area. The centerline of the main beam is the control line for the fixed position of the decking plate. The centerline of the main beam controls the overlapping width of the decking plate on the steel beam and determines the welding point position of the fusion welding between the decking plate and the steel beam. The centerline of the secondary beam will determine the welding position of the fusion welded studs. Because the specific position of the secondary beam flange is difficult to observe after the decking plate is laid, the centerline of the secondary beam and the width of the secondary beam flange are reflected on the centerline of the main beam. When fixing the studs, the centerline of the secondary beam and the width of the secondary beam flange should be reflected again on the decking plate on the surface of the secondary beam.

(2) In the material stacking area, the decking plates are sorted and cleaned layer by layer and area by area according to the material list, and the layer, area, and number are clearly marked with a marker pen, and accurately transported to the designated construction site.

(3) During hoisting, use special soft slings to ensure that the decking plate remains undeformed and the edges are not curled. Multi-story steel structures generally adopt a three-layer-per-column installation process (single-story structures are not discussed here). When installing the decking plates, the work should be carried out simultaneously with the steel structure columns and beams, with a difference of at least 3 layers. Therefore, the decking plates can only be hoisted through the beams and columns of the upper layer, and the crane operators should control the hoisting layer by layer between the beams and columns.

(4) Use a plasma cutter or shears to cut the corners. The allowance during cutting and marking should be controlled within 5mm. Measures should be taken during concrete pouring to prevent leakage.

(5) The connection between the decking plate and the side plate uses crimping pliers to crimp, connecting the single decking plates into a whole plate. First spot weld the side of the decking plate, then fix the two ends, and finally use studs to fix.

(6) Strengthen concrete curing.

Precautions

The general spacing of the steel structure column grid is 5~9.0m × 8~15m, the secondary beam spacing is 3m, and the decking plate material length is 4.97~8.97m, which makes transportation and installation difficult, especially for vertical hoisting of decking plates in circular areas, which is difficult to pass through the narrow space between the secondary beams from top to bottom, and disrupts the normal welding process of the secondary beams. Controlling the material length to 3~6m can avoid the problem of being unable to hoist between the secondary beams during vertical transportation.

Decking plates should be hoisted using special soft slings. Each time the hoisting is performed, check whether the soft sling is torn or cut. When the decking plate is placed on the steel beam, prevent it from protruding. When laying the material, the operators should wear safety belts and ensure that they are fixed to the surrounding safety ropes while laying.

Fusion spot welding is used for welding. Before welding, prepare edge scraps for arc welding test and adjust the welding current. Because there is no horizontal template and vertical support at the bottom of the decking plate, the material should not be too concentrated during concrete pouring, and a flat vibrating plate should be used to distribute and vibrate the concrete in time.

Product Specifications

Decking plate profile thickness: 0.8mm, 1.0mm, 1.2mm; width: 688mm~940mm; height: 51mm~76mm. The engineering floor decking plate and reinforced concrete structure work together as a composite structure. The decking plate is connected to the steel beam, the plate ends are fusion spot welded to the steel beam, and studs are used in the middle for penetration fusion welding with the steel beam; the decking plates are connected by using special clamping pliers to crimp and press the holes; the end caps are spot welded to the decking plate and steel beam using special galvanized end cap plates. If it is a decking plate with a curved area, the special-shaped cutting is done using a plasma cutter, with a smooth cut and intact galvanized coating. The decking plate welding uses manual arc spot welding, with E4303 welding rods, 3.2mm in diameter, and a fusion welding point of 16mm. The original design welding point spacing was 305mm, and the welding points were later doubled to ensure that the decking plate does not deform when the operators walk on it, and that the ends of the decking plate do not leak during concrete pouring. When the floor structural elevation is inconsistent, steel is added to make the horizontal structure transition in steps. When the elevation is lowered, angle steel is welded to the web of the I-beam; when the elevation is raised, channel steel is welded to the flange of the I-beam. When there are reserved openings in the floor,

Composite floor slab

Category:

Other content

Triangular truss steel structure