Common types of trusses include steel trusses, reinforced concrete trusses, prestressed concrete trusses, timber trusses, steel-timber composite trusses, and steel-concrete composite trusses. Trusses are classified by their shape into triangular trusses, trapezoidal trusses, polygonal trusses, parallel chord trusses, and open-web trusses. When selecting a truss type, the purpose, material, support method, and construction conditions of the truss should be comprehensively considered. The goal is to minimize the materials and labor required for manufacturing and installation while meeting the usage requirements.

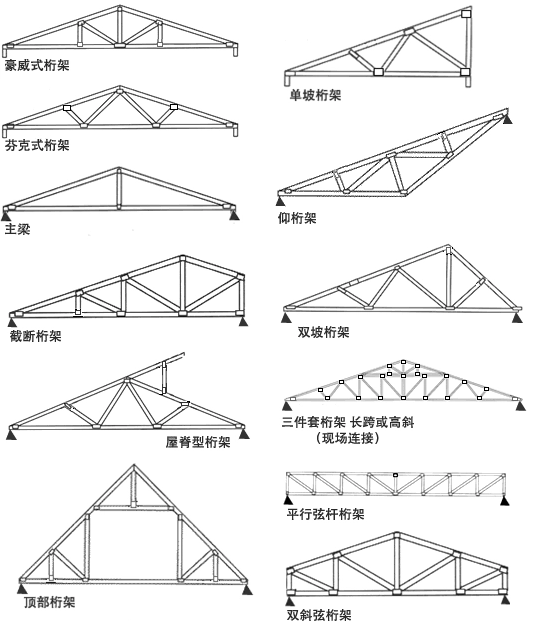

Truss Classification

Structural Classification

Triangular Truss: Under uniformly distributed nodal loads along the span, the axial forces in the upper and lower chords are maximum at the ends and gradually decrease towards the mid-span; the axial forces in the web members are the opposite. Due to the large difference in internal forces in the chord members, triangular trusses are not very efficient in material use and are often used in roof trusses for tile roofs.

Trapezoidal Truss: Compared with triangular trusses, the stress on the members is improved, and it can more easily meet the process requirements of some industrial plants when used in roof trusses. If the upper and lower chords of a trapezoidal truss are parallel, it is a parallel chord truss. The stress on the members is slightly worse than that of a trapezoidal truss, but the types of web members are greatly reduced. They are often used in bridges and wharves.

Polygonal Truss: Also known as a broken-line truss. The upper chord nodes are located on a quadratic parabola. If the upper chord is arched, the bending moment generated by the inter-node load can be reduced, but the manufacturing is more complex. Under uniformly distributed loads, the shape of the truss is similar to the bending moment diagram of a simply supported beam, so the axial force distribution in the upper and lower chords is uniform, and the axial force in the web members is small, resulting in the most economical material usage. This is a commonly used truss type in engineering.

Open-Web Truss: It basically uses the shape of a polygonal truss, with straight lines between the upper chord nodes and no diagonal web members, only connected to the upper and lower chords by vertical web members. The axial force distribution is similar to that of a polygonal truss, but the bending moment at the end of the member changes significantly under asymmetrical loads. The advantage is that fewer members intersect at the nodes, making construction and manufacturing easier.

Product Classification

1. Fixed Truss: The most robust type of truss, highly reusable, the only drawback is the higher transportation cost. Products are available in square and round tubes.

2. Folding Truss: The biggest advantage is the low transportation cost, with slightly lower reusability. Products are available in square and round tubes.

3. Butterfly Truss: The most artistic type of truss, with a unique and beautiful shape.

4. Ball Joint Truss: Also known as a ball joint frame, it has a beautiful shape and good robustness, and is also the most expensive type of truss.

Truss Requirements

Sufficient strength—no fracture or plastic deformation; sufficient rigidity—no excessive elastic deformation; sufficient stability—no collapse due to a sudden change in the equilibrium form; good dynamic characteristics—earthquake resistance and wind resistance. Truss design requirements: There must be members that meet the requirements; there must be good connectors, including rivets, pins, and welded joints. These involve the type of truss, the size and material of the members, but first, the static analysis.

Form Selection

From a mechanical point of view, when the truss shape is similar to the bending moment diagram of a simply supported beam, the axial force distribution in the upper and lower chord members is uniform, the axial force in the web members is small, and the material usage is most economical; from the material and manufacturing aspects, timber trusses are made into triangles, steel trusses use trapezoidal or parallel chord shapes, and reinforced concrete and prestressed concrete trusses are preferably polygonal or trapezoidal. The ratio of the height to the span of the truss is usually 1/6~1/12, and specific regulations are given in design manuals and specifications. Trusses have a wide range of applications. When selecting a truss form, the purpose, material, support method, and construction conditions of the truss should be comprehensively considered. The principle of selecting the optimal form is to minimize the materials and labor required for manufacturing and installation while meeting the usage requirements.

Calculation Points

Trusses used in building construction generally only undergo static calculations; for dynamic loads such as wind, earthquake, running vehicles, and operating machinery, they are converted into equivalent static loads multiplied by a dynamic coefficient for calculation; for special and important trusses subjected to dynamic loads, such as large-span bridges and aircraft wings, dynamic analysis must be performed according to the dynamic loads (see Loads).

Plane trusses are generally calculated according to ideal pin-jointed trusses, i.e., it is assumed that the loads are applied at the truss nodes (if the loads are applied between nodes, they can be converted to nodal loads according to the simply supported beam), and all members of the truss are in the same plane, the centroidal axes of the members are on a straight line, and the nodes are freely rotating pin joints. For statically determinate trusses in an ideal state, the axial forces of the members can be taken as unknowns, and the axial tensile or compressive forces of the members under known loads can be obtained using static methods or graphical methods (see Static Analysis of Bar Structures).

The nodes of engineering trusses are generally nodes with a certain rigidity rather than ideal pin joints. The bending stress and axial stress caused by the influence of node rigidity are called secondary stresses. The calculation of secondary stresses needs to consider the axial deformation of the members, and can be solved by the method of hyperstatic structures or the finite element method.

Space trusses are composed of several plane trusses. The loads can be decomposed into components in the same plane as the truss and calculated as plane trusses, or calculated using the finite element method for spatial pin-jointed bar systems.

According to the material used for the truss members and the internal forces obtained from the calculation, the appropriate section should be selected to ensure the overall stiffness and stability of the truss, as well as the strength and local stability of each member, to meet the usage requirements.

The overall stiffness of the truss is ensured by controlling the maximum vertical deflection of the truss to not exceed the allowable deflection; the out-of-plane stiffness of the plane truss is poor and must be ensured by the support system. Support systems include upper chord support, lower chord support, vertical support, and trusses

TAG:

Truss

Category:

Other content

Triangular truss steel structure